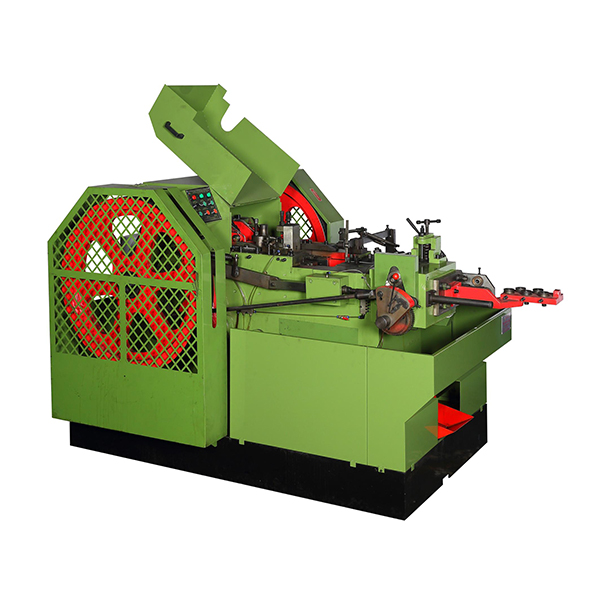

Serje Z12 1-Die 2-Blow Cold Heading Machine

Karatteristiċi Ewlenin

1、Il-qafas prinċipali tal-magna u l-muntun eċċ ġew ittrattati bis-sħana għar-rilaxx tal-istress intern u normalizzati wara l-ikkastjar biex tiġi evitata kwalunkwe deformazzjoni f'operazzjoni fit-tul u żżomm preċiżjoni stabbli;

2、Cut-off romblu huwa appoġġjat fuq iż-żewġ naħat biex jiksbu riġidità massima u qtugħ stabbli;

3、Disinn sempliċi u razzjonali biex jassorbi x-xokk li jiċċaqlaq 'il fuq u' l isfel ta 'slider punch b'aġġustament ta' malajr u manutenzjoni faċli;

4、Slider prinċipali tat-tip Overam b'inforri magħmulin minn azzar liga għolja jippermetti preċiżjoni twila u stabbli;Il-PKO jipprevjeni t-tixrid tal-partijiet foloz milli jiffurmaw die qabel ma jiġu knock out;

5、Safety pins huma użati għall-knock out u cut-off mekkaniżmu biex jipprevjenu kwalunkwe ħsara tal-partijiet tal-magni;

6、 "Inching", "Single Stroke" u "Continuous Running" jagħmel l-allinjament tal-magna ma 'għodda ħafna faċli.

Parametri tal-Prodott

| Mudell | Dijametru massimu (mm) | Tul massimu (mm) | Ram Stroke (mm) | Ir-rata tal-ħruġ (pcs/min) | Moffa Prinċipali (mm) | Cut-off Die (mm) | Punch Die (mm) | Daqs tal-Cutter (mm) | Dimensjonijiet Mekkaniċi (mm) | Mutur Ewlieni (kw) | Piż nett (kg) |

| Z12-3 | 4 | 20 | 40 | 160-190 | φ20 * 36 | φ13 * 25 | φ18 * 50 | 6*25*42 | 1.4 * 0.75 * 0.9 | 1.1 | 624 |

| Z12-4 | 5 | 40 | 60 | 140-170 | φ32 * 60 | φ15 * 30 | φ25 * 65/70 | 10 * 35 * 72 | 1.8 * 0.85 * 1.5 | 2.2 | 1274 |

| Z12-5 | 7 | 60 | 90 | 110-140 | φ32 * 80 | φ20 * 35 | φ30 * 75 | 10 * 35 * 72 | 2.3 * 1.08 * 1.25 | 3 | 2080 |

| 80 | 110 | 90-110 | φ32 * 100 | φ20 * 35 | φ30 * 80 | 10 * 35 * 72 | 2.4 * 1.15 * 1.35 | 2145 | |||

| 100 | 130 | 80-100 | φ35 * 120 | φ20 * 35 | φ30 * 80 | 10 * 35 * 72 | 2.5 * 1.15 * 1.35 | 2210 | |||

| 150 | 190 | 80-100 | φ40 * 180 | φ20 * 35 | φ35 * 100 | 10 * 35 * 72 | 2.6 * 1.15 * 1.35 | 2990 | |||

| Z12-6 | 9 | 90 | 120 | 80-100 | φ50 * 120 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 | 2.7 * 1.4 * 1.6 | 5.5 | 3380 |

| 120 | 150 | 70-90 | φ50 * 150 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 | 2.8 * 1.4 * 1.6 | 3640 | |||

| 150 | 190 | 60-70 | φ50 * 180 | φ24 * 40 | φ35 * 100 | 12 * 35 * 77 | 3.0 * 1.4 * 1.6 | 4160 | |||

| 170 | 230 | 50-60 | φ50 * 220 | φ24 * 55 | φ35 * 120 | 12 * 35 * 77 | 3.2 * 1.4 * 1.6 | 4360 | |||

| 200 | 250 | 40-50 | φ50 * 240 | φ24 * 55 | φ35 * 120 | 12 * 35 * 77 | 3.65 * 1.4 * 1.65 | 4940 | |||

| 250 | 290 | 30-45 | φ50 * 290 | φ24 * 60 | φ35 * 140 | 12 * 35 * 77 | 3.7 * 1.5 * 1.7 | 5460 | |||

| Z12-8 | 11 | 120 | 160 | 60-80 | φ60 * 160 | φ28 * 45 | φ40 * 120 | 12 * 42 * 90 | 3.75 * 1.6 * 1.8 | 7.5 | 4940 |

| 150 | 190 | 60-70 | φ60 * 190 | φ28 * 45 | φ40 * 120 | 12 * 42 * 90 | 3.9 * 1.6 * 1.8 | 6240 | |||

| 200 | 250 | 40-50 | φ60 * 240 | φ28 * 60 | φ40 * 150 | 12 * 42 * 90 | 4.15 * 1.6 * 1.85 | 6500 | |||

| 250 | 290 | 30-45 | φ60 * 290 | φ28 * 60 | φ40 * 150 | 12 * 42 * 90 | 4.3 * 1.6 * 1.9 | 7800 | |||

| Z12-10 | 13 | 120 | 160 | 50-60 | φ80 * 160 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 | 4.8 * 1.8 * 1.32 | 11 | 8450 |

| 180 | 230 | 50-60 | φ80 * 220 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 | 4.8 * 1.8 * 1.32 | 8650 | |||

| 220 | 270 | 40-50 | φ80 * 260 | φ35 * 50 | φ50 * 150 | 16 * 55 * 115 | 5.0 * 1.8 * 1.32 | 9100 | |||

| Z12-12 | 15 | 150 | 190 | 40-50 | φ88 * 200 | φ45 * 60 | φ60 * 180 | 18 * 60 * 125 | 5.2 * 1.9 * 1.8 | 18.5 | 14040 |

| 200 | 250 | 30-40 | φ88 * 260 | φ45 * 60 | φ60 * 180 | 18 * 60 * 125 | 5.2 * 1.9 * 1.8 | 14300 | |||

| 280 | 330 | 30-40 | φ88 * 340 | φ45 * 60 | φ60 * 180 | 18 * 60 * 125 | 5.2 * 1.9 * 1.8 | 15600 | |||

| 300 | 350 | 25-35 | φ88 * 360 | φ45 * 60 | φ60 * 180 | 18 * 60 * 125 | 5.2 * 1.9 * 1.8 | 15860 |